Minimizing spindle idle time is essential for maximizing efficiency in CNC machining. High-speed machining uses a high-speed spindle to produce faster cutting feed rates through material. As a result, cycle times per part are reduced, allowing more parts to be made per shift and improving productivity. DATRON CNC machines excel in high-speed machining and streamline workflow, reducing spindle idle time and enhancing production efficiency.

Why Spindle Idle Time Matters in CNC Machining

When evaluating CNC equipment, the cycle time per part is often a primary focus.. Production engineers will calculate an ROI (Return on Investment) with this data taken during their due diligence. If you were producing the same part over the next 5 – 10 years, cycle time should be the sole focus. However, if you run different jobs with various materials and workholding methods throughout a production week, the entire process must be evaluated and measured to ensure efficiency and consistency. What can be overlooked is the workflow or time it takes to produce your parts from start to finish. When setting up to run the next job, your spindle is not producing parts. Spindle idle time is one of the most important considerations when researching CNC equipment.

Spindle Idle Time Explained: A Real-World Example

An example of how spindle idle time can impact your business is our experience with a customer in 2006. They were manually drilling tiny holes in ceramic nozzles on specialized drill presses that approximately five employees operated. They wanted to reduce labor costs by automating this process on a CNC machine. At their request, we performed a time study using an automated pick and place system to load a blank nozzle from a pallet into a 4th axis, drill the complete part, and return it to a pallet of finished parts. The cycle time of the automated process was slower than the manually drilled nozzle because the operator was much faster and more agile than the pick and place system. Although they were disappointed with the cycle time, they moved forward anyway because it would reduce costs due to the labor reduction.

To their surprise, the slower automated process almost produced double the output over a month because of spindle idle time in the manual process. Although the automated pick and place system was not as fast as a human operator, it was constant. The machine never stopped moving, and the spindle never stopped turning. The manual process performed by operators incurred spindle idle time because the operators took breaks, had chats, went to the bathroom, and sometimes missed a day or two due to sickness. They never calculated the spindle idle time in their manual production process, which could have impacted their decision not to move forward. You must look at the entire workflow and calculate spindle idle time to evaluate a solution for your type of production parts properly.

How to Reduce Spindle Idle Time: Six Key Areas

There are many ways to reduce spindle idle time. Improving efficiencies throughout your workflow will dramatically impact your overall productivity. Six areas can impact your production output.

1. CAM or Programming

CAM or programming is typically done offline and should not impact production output. However, in some cases, it can still cause disruptions. It is critical that your machine is not idle waiting for parts to be programmed. Prevent disruptions by using experienced programmers, reliable software like Fusion 360, and machine control simulations for validation before machining. Additionally, a robust post processor between your CAM software and machine can reduce or eliminate errors and manual changes to the output code. DATRON’s next Control has a very experienced and proven post processor to Fusion with many automated features such as shared tool libraries and 3D probing. The next Control also has a comprehensive 3D simulation interface to simulate offline machining. In most cases once the part is cammed and validated, you are ready to machine without any manual edits.

2. Setup or Changeover

Proper machine setup is crucial for part success but can cause significant spindle idle time. Ensuring the correct tools are loaded into the magazine to match the program requirements is essential. A post-processor can significantly streamline this setup if it is linked to the machine’s tool database, such as the post for DATRON’s next Control Software and Fusion 360. Additionally, having a machine with a high-volume tool capacity gives you greater flexibility. Even if a job requires only a few tools, having up to 143 tools preloaded in the magazine for different cutting operations eliminates the need for manual tool changes, saving valuable time. DATRON offers high-capacity tool magazines on all their CNC machines with automatic tool length measurements that save time.

3. Workholding and Part Setup

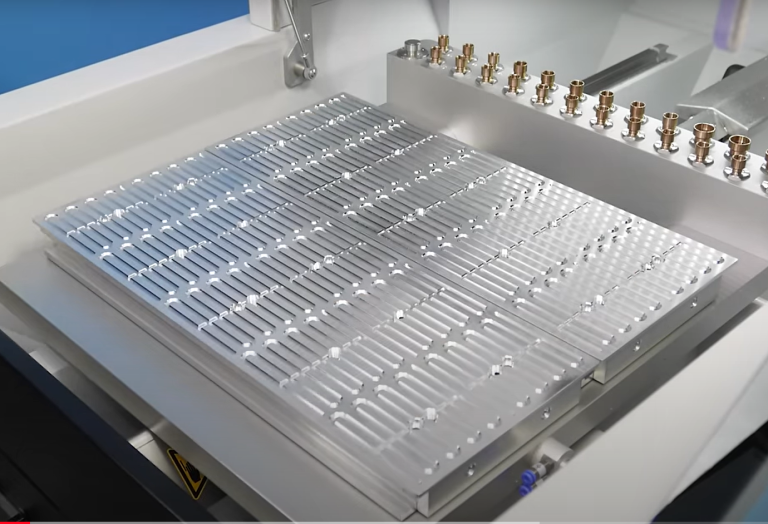

Once your tools are configured, material will be added next. Mounting material to your machining table can take significant time, depending on the application and tolerances required. For example, securing large, flat sheet material can be challenging because it does not easily fit into a vice. Also, using screws or adhesives takes a lot of additional time, both pre and post-changeover. DATRON offers an innovative vacuum table system that securely mounts flat materials in seconds with minimal setup. Additionally, they provide a range of pneumatic clamping systems that streamline part changeovers by automatically activating through an I/O connection and code directly from the posted CAM program.

Find the part origin once the tools are set up and the material is mounted. Depending on the application, finding the part origin may need to be extremely precise, which is time-consuming. DATRON offers a range of solutions to accelerate this process, including camera systems that visually locate parts or automatically detect markings and fiducials with micron-level precision.DATRON offers integrated touch probes for edge-finding, surface measurement, and compensating for thickness or mounting variances. By default, it measures two points along an edge and orients the machine axis in line with the mounted part, accounting for any rotation. You don’t have to trim your workpiece perfectly, just somewhere in the ballpark.

DATRON provides a unique conical registration system for fast and precise workholding alignment on the machining table. The stainless-steel mounts sit flush with the table, and their conical shape ensures perfect registration with the machining axes in X, Y, and Z. This gives the operator the ability to dismount and mount a new pallet held by either screws or in seconds by vacuum. Prestored work offsets in the DATRON next Control allow you to coordinate with a pallet location. The operator can remove an entire pallet setup, mount a new pallet, and load the prestored origin in under a minute. This system is excellent for repeat work that requires unique work holding. You can even mount a vice to a pallet for quick installation and removal.

4. Quality Control and Part Validation

In some cases, you may have to validate a part before you can run a job. Waiting for the CMM department to confirm part tolerance while your machine sits idle is frustrating and costly. A knowledgeable, experienced CAM person, a skilled machine operator, and a tight-tolerance machine tool can minimize rejected parts. Additionally, features like precision tool length measurement and an integrated probe help reduce rejected parts caused by setup errors by allowing adjustments and re-validation before machining. Sometimes, there is no way around measuring your part once, but you can control having to measure your parts twice.

5. Automating Production to Reduce Spindle Idle Time

The more you can automate and reduce the machine from stopping and waiting for an operator to load the next part, the more throughput you will have. It often makes little sense to program a robot, cobot, or pallet system for a small production run. There are ways that you can automate your process and minimize your machine’s idle time from stops and reloads. Nesting parts is a simple way to make multiples without additional setup time. Cookie-cutting parts from sheet material allows the machine to run parts continuously without stopping.

Another advantage to nesting is you can amortize tool change times over several parts. Machining 20 parts at once with three tools requires only three tool changes, versus 60 when machining individually. If the part takes 5 minutes to machine, you are now loading the machine every hour and forty minutes instead of every 5 minutes. DATRON offers large format machines with full-size vacuum tables, allowing you to nest multiple parts quickly and easily.

The next Control software includes a nesting feature, allowing the process to be completed directly at the machine control instead of requiring CAM software. The more you can do to reduce the requirement of an operator to load and unload a part, the more substantial the impact on your overall production will be. A perfect example is the scenario of drilling the ceramic nozzles mentioned earlier.

6. Material and Tool Inventory Management

Having a machine idle waiting for material is a nightmare scenario. Staying ahead of production and having the right materials and tools ready is key to minimizing spindle idle time.Creating the CAM program days or weeks before you machining the part will help identify the size of material needed and the types of tools required. It also enables you to determine how you will secure the part and any special work holdings needed. If you do not have the luxury of being that far in front, purchasing your material and tools from a reliable supplier is essential to minimize spindle idle time. At DATRON, we have over two million dollars in inventory of tools and parts with an easy-to-use online shop to receive cutting tools quickly, in most cases, the next day.

Preventative Maintenance and Downtime Reduction

Taking your CNC machine offline for maintenance is essential for sustaining equipment and functionality. Any excessive downtime due to improper or lack of care of equipment can be costly. Newer and more reputable machine tools will incur less maintenance downtime, but you must consider other factors. Coolant or flood systems can significantly increase maintenance time due to the constant upkeep these systems require. Cleaning filters and changing fluids regularly all lead to increased spindle idle time.

DATRON takes a different approach with its MQL (minimum quality lubricant) system. This system uses minimal coolant and evaporates away clean without any residue. Therefore, there are no filters to clean and fluids to exchange. Parts do not require any de-greasing or washing operation afterward, which helps decrease overall part costs. DATRON also offers a preventative maintenance program that helps maintain your systems and minimize downtime. Maintenance includes replacing worn parts, cleaning air filters, adjusting axis calibrations, and updating software. Coordinate these maintenance programs in advance to properly plan the event for your production schedule.

Conclusion: Reduce Spindle Idle Time with DATRON CNC Machines

Minimizing spindle idle time is crucial for maximizing efficiency and production output in CNC machining. While cycle time per part is important, optimizing the entire workflow—from programming and setup to material handling and automation—ensures continuous operation and profitability. Reducing downtime increases throughput and lowers operational costs, making your machining process more efficient and cost-effective. DATRON CNC machines are designed to streamline processes, reduce downtime, and keep your spindle running with minimal interruptions.

Contact DATRON today to learn how their cutting-edge technology can enhance your machining operations and boost productivity.