North America | Global

North America | Global

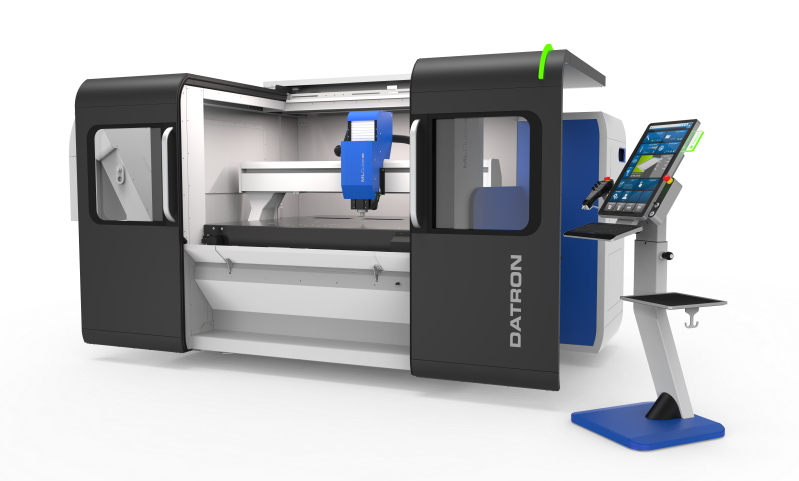

The DATRON MLCube Pro delivers efficient material handling, intelligent automation, and superior chip management to maximize productivity and minimize downtime.

The DATRON MLCube Pro is the premium model in the MLCube series, designed for high-performance machining with maximum efficiency. Built for high metal removal rates, it features automatic hinged doors and crane-loading capability, making material handling seamless and reducing operator workload. Its external ToolAssist system allows tools to be loaded and unloaded during machining, minimizing downtime and ensuring continuous production.

Engineered for industrial-scale efficiency, the MLCube Pro includes an optimized chip management system with an additional chip conveyor, ensuring effective debris removal and uninterrupted machining. Its high-frequency spindle delivers superior surface finishes on aluminum, non-ferrous metals, composites, and engineered plastics. Combined with an intuitive touchscreen CNC control, the MLCube Pro is easy to operate, allowing manufacturers to start producing high-precision parts immediately while maintaining the flexibility needed for large-format machining.

Easily machine small nested parts or large workpieces with the DATRON MLCube Pro’s expansive work area and advanced vacuum table system. Designed for high-speed, high-precision machining, it excels in applications such as:

| Name | Detail |

|---|---|

| Travel | 1,520 mm x 1,150 mm x 245 mm (60” x 45” x 10”) (X, Y, Z) |

| Spindle | 3.0 kW–4.0 kW HF spindle up to 40,000rpm; HSK-E 2 |

| Feed | Up to 22 m/min (866 in/min) |

| Tool Changer | DATRON ToolAssist 60 or 143 stations with HSK-E 25 with integrated length sensor (optional) |

| Control System | DATRON next |

| Working Area | 1,500 x 1,000 x 200 mm (59" x 39" x 7.5") |

| Footprint | 4,500 x 2,430 x 2,140 mm (177" x 96" x 84") (W x D x H) |

| Weight | Approx. 3,200kg (7,055 lbs.) |

| Machining Table | Mineral-cast machine bed; integrated conical thread; full or cut-out table |

| Touch Screen | 24” multi-touch screen with user-friendly hand-held control unit |

| Power | From 0.6 to 4.0 kW |

| Name | Detail |

|---|---|

| Linear Scales | For extra precision applications, a linear scale option is available |

| Coolant | Integrated high-pressure minimum quantity misting system |

| Camera | Optical camera in combination with touch screen visually finds parts |

| Probe | Integrated 3D Renishaw Touch probe for precision part finding |

| 4th Axis | for machining cylindrical parts or multi-sided parts |

| Vacuum Table Work Holding | for machining nested parts from flat thin sheet materials |

| Clamping Systems | low profile mechanical and pneumatic vices with soft jaws |

| Dust Extraction Head | for vacuuming and removal of dangerous or abrasive dust particles |

| Remote Software Monitoring | check in on the status of your machine away from the shop |

| Tool Life Management | tool breakage monitoring with automatic duplicate tool replacements |

| Surface Profiling | measurement and mapping of 3D surfaces and compensation of variances |

| Automation Integrations | 24 volt I/O connections for robots / cobots / pallet systems |

DATRON CNC machines and high-speed spindles will increase your feed rates and reduce faster cycle times. The machines and software are optimized so that the entire machining process or workflow is fast and efficient saving you time and money.

Our DATRON Experts Help Many Customers Bring Manufacturing In-House. Reach Out To Our Team To See Which Machine And Accessories Are The Right Fit For Your Parts.