North America | Global

North America | Global

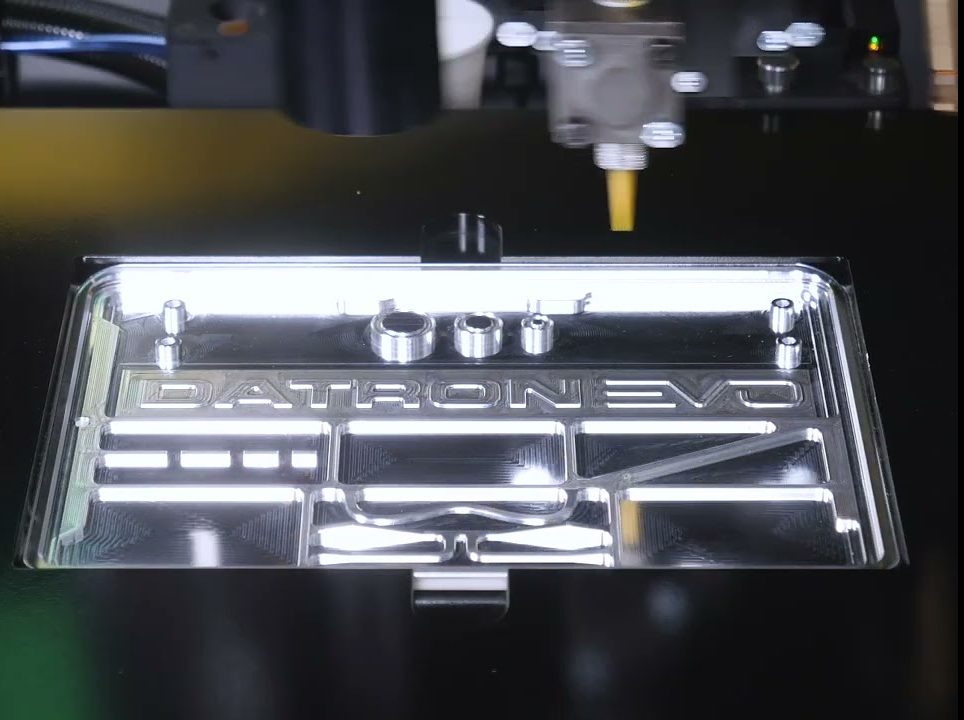

Maximize precision and efficiency with the DATRON evo 600—your solution for high-performance dispensing.

Achieve precise dispensing results and unmatched efficiency with advanced technology and user-friendly design.

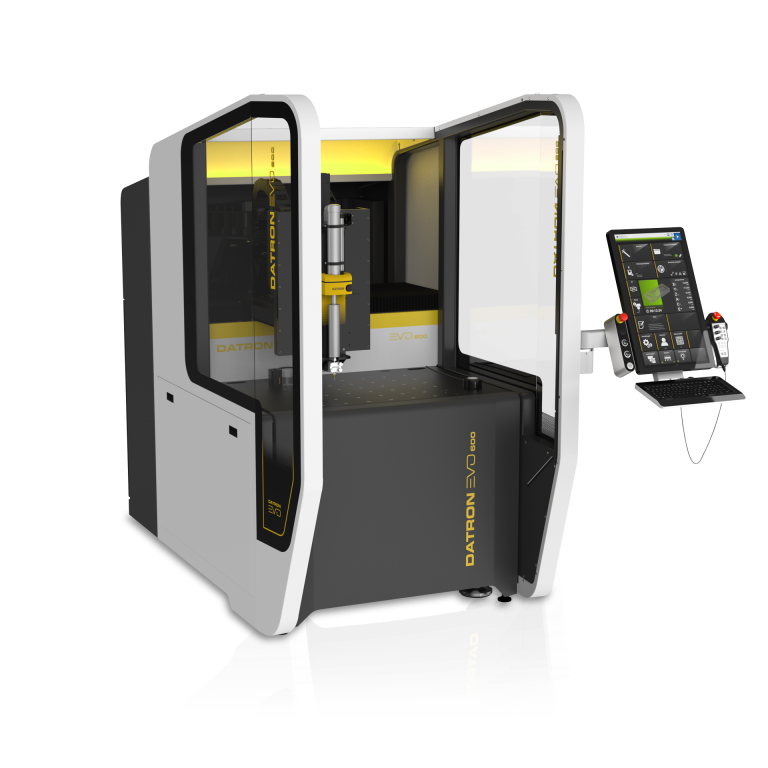

Experience a dispensing system that revolutionizes your production process with the DATRON evo 600. Thanks to the innovative DATRON next control system and precise dispensing technology, you can achieve outstanding dispensing results. The open cabin not only offers easy access for loading and unloading, but also guarantees maximum safety thanks to integrated light curtains. The user-friendly operator interface of the pioneering DATRON next control enables intuitive handling, while the modular design offers flexibility for configuration. Maximize your efficiency and competitiveness with the DATRON evo 600.

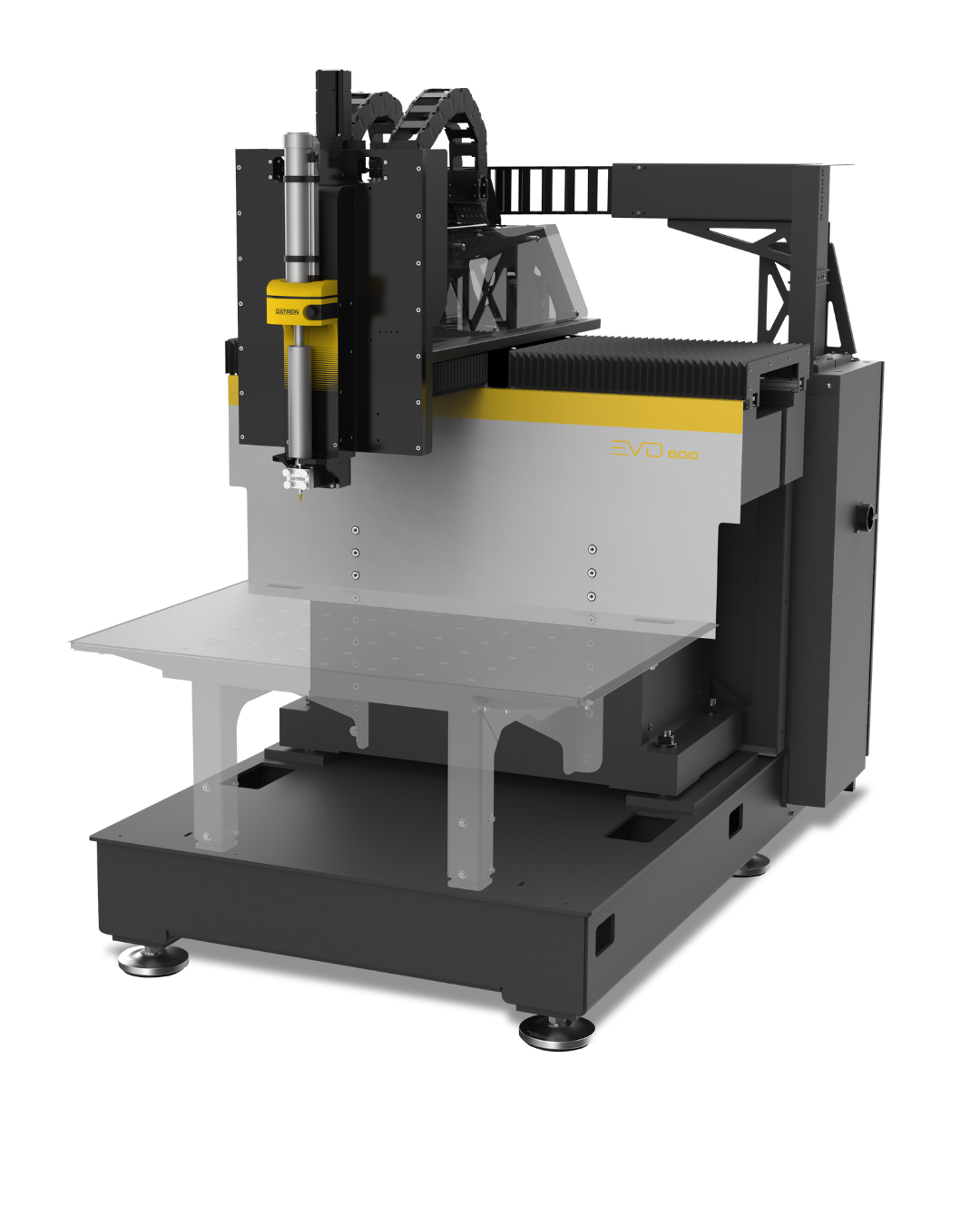

The DATRON evo 600 integrate combines the outstanding features of the DATRON evo 600 and also offers maximum flexibility for integration into fully automated production lines. This cabinless version with a solid base from and lowerable machine table was developed to ensure maximum flexibility and efficiency. The simple connection options for customized workpieces loading make it ideal for industrial series production.

The DATRON next control forms the heart of our production technology. Thanks to continuous development, you benefit from the latest functionalities at all times and ensure the future viability of your production. The intuitive operating concept simplifies processes and reduces training costs. Forward-looking software options allow you to further reduce error rates and significantly lower follow-up costs.

| Name | Detail |

|---|---|

| Maximum Component Height | 250 mm (10 inches) Can be increased to 450 mm (17 inches) at the factory. |

| Travel | 620 mm x 515 mm x 240 mm (24” x 20” x 9.5”) (X, Y, Z) |

| Traversing Speed X, Y | up to 50m/min |

| Traversing Speed Z | up to 23m/min |

| Control System | DATRON next |

| Working Area | 1,500 x 1,000 x 200 mm (59" x 39" x 7.5") |

| Footprint | 2,410 x 2,280 x 1,950 mm (95" x 90" x 77") (W x D x H) |

| Machining Table | Aluminum table with M6 tapered thread grid (100mm x 100 m) |

| Operating Terminal | 24' multitouch display with additional manual control panel |

| Safety Concept | Safety light curtain type 4 |

| Power | 400 V, CEE 16 A, 4.5 kVA |

| Installation Dimensions with Operating Terminal (W x D x H) | 1,890 mm x 2,500 mm x2,150 mm ( 74 x 98 x 85 inches) |

| Installation Dimensions without Operating Terminal (W x D x H) | 1,290 mm x 2,200 mm x 2,150 mm (51 x 87 x 85 inches) |

| Weight | approx. 1,900 kg (4,1882 lbs.) |

DATRON CNC machines and high-speed spindles will increase your feed rates and reduce faster cycle times. The machines and software are optimized so that the entire machining process or workflow is fast and efficient saving you time and money.

Our DATRON Experts Help Many Customers Bring Manufacturing In-House. Reach Out To Our Team To See Which Machine And Accessories Are The Right Fit For Your Parts.