CNC machining thermal management components is increasingly important as electronic devices become smaller and more powerful. Managing the heat they generate is essential to extend component life, maintain performance, and ensure safety.

Types of Thermal Management Devices

Thermal management devices generally fall into five categories:

-

Heat sinks

-

Air-cooled systems (fans)

-

Liquid-cooled systems (cold plates)

-

Insulation materials (to isolate heat)

-

Thermal interface materials (to enhance conductivity)

Challenges of CNC Machining Thermal Management Devices

Heat sinks and cold plates are commonly made from highly conductive materials such as aluminum and copper. Efficiently machining these materials presents unique challenges, which this article will explore in more detail, focusing specifically on heat sinks and cold plates.

CNC Machining Heat Sinks: Design Demands and Limitations

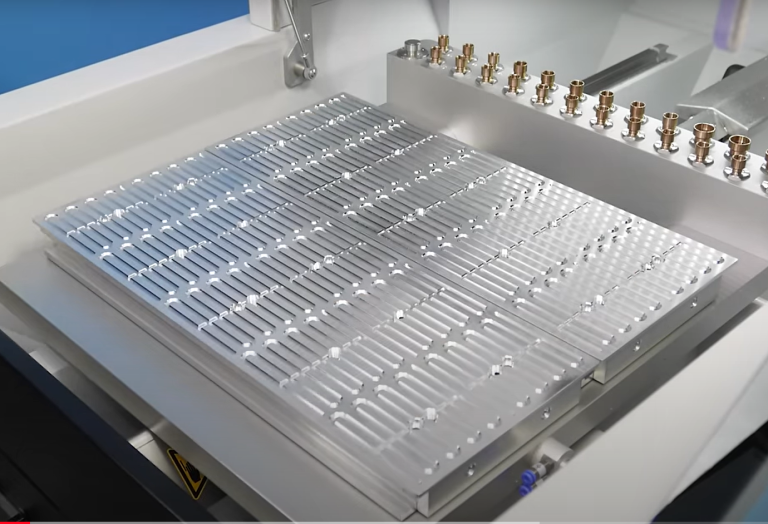

Heat sinks are typically constructed from aluminum or copper and dissipate heat from components like CPUs, GPUs, and power transistors. Heat sinks are designed with as much surface area as possible to maximize heat dissipation within a limited space, usually achieved through closely spaced, thin fins.

Prototyping or producing short runs of these designs is complex. The deep, narrow channels require small-diameter, long-reach cutting tools, which are prone to breakage, even at slow feed rates on conventional CNC machines. EDM (Electrical Discharge Machining) can be used to burn these channels, but it is a slow, two-step process that involves machining an electrode and then burning the metal. Furthermore, electrodes may need to be redressed between burns, especially when tight tolerances are required.

Alternative methods, such as metal additive manufacturing, are possible but come with high costs and slow production speeds. Acid etching is sometimes used, but it isn’t effective for deep channels and faces increasing restrictions due to environmental concerns.

DATRON High-Speed CNC Solutions for Thermal Management

DATRON offers high-speed CNC systems that are ideal for machining intricate details with small tools. With spindles running up to 60,000 RPM, these machines achieve fast feed rates and lower production costs for aluminum and copper components. These precision German-engineered systems minimize vibration and tool run-out, reducing the risk of tool breakage.

A high-pressure ethanol mist coolant system cools the tool, clears chips from deep channels, and allows for sustained high-speed cutting. The time required to EDM a heat sink is often comparable to machining it with a DATRON system, but without the added step of machining an electrode.

DATRON also provides a line of micro-grain carbide tools specifically designed for aluminum and copper. These tools offer high feed rates and burr-free edges. The clean-evaporating ethanol coolant eliminates the need for additional finishing steps.

Thermal Management Devices: Cold Plates

Like heat sinks, cold plates are commonly made from aluminum or copper. They consist of layered metal plates with internal liquid channels for thermal regulation. Although the channels are often not as deep as those in heat sinks, they require high-precision machining to maintain narrow and consistent grooves for efficient heat transfer.

Standard CNC machines with spindles under 20,000 RPM are inefficient for this application. EDM remains a time-intensive, two-step process. As with heat sinks, DATRON systems offer a superior alternative for producing cold plates.

Benefits of Using DATRON for Thermal Management Devices

DATRON machines are built on a gantry design, providing a large work area while occupying minimal floor space. This is especially beneficial for thermal management devices, whether you’re machining large single pieces or nesting multiple parts.

For example, the DATRON M8Cube offers a 39″ x 27.5″ travel area while only requiring 69″ x 69″ of floor space. This allows for machining long heat sinks, like an aluminum extrusion, large cold plates, or multiple smaller parts from a single sheet. A vacuum table holds the material in place, and a sacrificial cardboard layer allows for through-cutting without damaging the table.

Specific DATRON models are equipped with linear scales that deliver micron-level accuracy for applications requiring tight tolerances. To further ensure precision, the spindles feature liquid-chilled refrigeration units that maintain a consistent temperature in the spindle bearings, minimizing depth variation caused by thermal expansion.

Surface Mapping for Precision Z-Axis Control

DATRON also offers an advanced surface-mapping touch probe that compensates for surface irregularities. This feature is especially valuable when working with large sheets of material, as it significantly reduces setup time. The probe measures a matrix of points across the material’s surface, automatically allowing the Z-axis to adjust during machining. This results in more accurate and consistent depth control, critical when machining thin materials with precision requirements.

User-Friendly Controls

DATRON machines feature an industry-leading, intuitive interface – the next Control Software. This touchscreen-based control system offers a highly visual, smartphone-like experience. The app-driven software supports familiar gestures such as swipe, pinch, and tap, making it easy to learn and use. One of the key advantages of the next control is that it eliminates the need for a traditional machinist. Designers and engineers can operate the machine, making it ideal for prototyping environments where speed and flexibility are essential. Engineers can independently produce their parts without delay when production lines are backlogged. DATRON machines are also designed with modern workspaces in mind—they’re clean, quiet, and compact enough to fit directly into an engineer’s lab. Some models run on standard single-phase power and are small enough to fit in a freight elevator.

Why DATRON Leads in CNC Thermal Machining

DATRON’s high-speed machining technology excels at producing intricate parts in non-ferrous materials with small tools, making it ideally suited for thermal management devices like heat sinks and cold plates. With faster production times, cleaner finishes, and reduced secondary processing, DATRON systems offer a clear advantage in this demanding application.