As global manufacturing costs rise and international sourcing becomes less reliable, many manufacturers are turning to in-house machining to avoid tariffs. Now is the time to gain control over your production, cut costs, and reduce dependency on overwhelmed domestic suppliers. DATRON’s CNC technology makes the shift seamless—even if you’re not a machinist.

In today’s climate of economic uncertainty, businesses must rethink and adapt their operations to stay competitive. The current administration has implemented tariffs to encourage the return of manufacturing to the United States, with steep financial penalties for companies that continue sourcing parts from overseas—including our neighbors to the north and south.

Whether or not you agree with this strategy, one thing is clear: the landscape is shifting. Companies that move quickly to adapt will gain a strategic advantage. If you’re currently outsourcing machined parts internationally, ow is the time to avoid tariffs with in-house machining. Doing so could help you avoid tariffs, reduce costs, and gain more control over your supply chain.

Even if your company doesn’t directly outsource machined parts abroad, you’ll likely feel the ripple effects. OEMs that previously sourced parts overseas will now turn to local machine shops. What was once a costlier alternative is now more competitive, especially with tariffs in place—and the real possibility of them increasing. Domestic machine shops may quickly become overwhelmed, potentially leading to extended lead times and delays. Even longstanding supplier relationships may be deprioritized if larger, more lucrative contracts come into play.

How to Avoid Tariffs with In-House Machining—Even Without a Machine Shop

So, how can you make the leap from outsourcing to producing machined parts internally—especially if you’re not a machine shop, don’t have machinists on staff, and aren’t sure what equipment or software you even need?

These are valid concerns. You may wonder: What if I invest in equipment and the tariffs are later lifted?

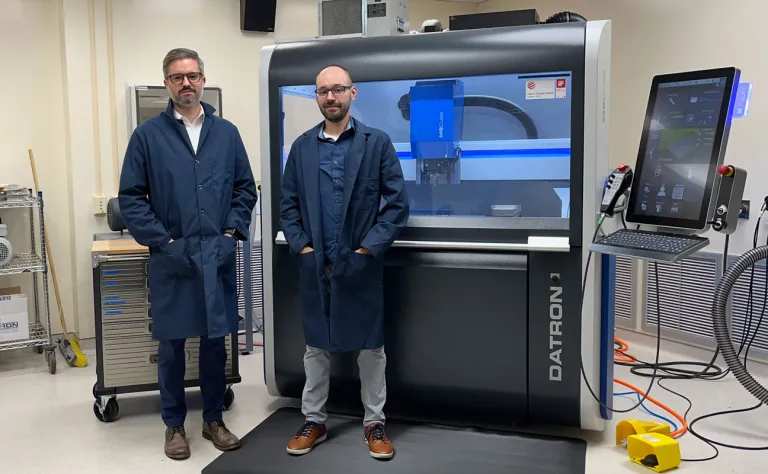

Fortunately, there’s a solution that can make this transition far more accessible and less risky: DATRON.

A Machine Built for First-Time Users

More than half of DATRON’s customers are first-time buyers of CNC equipment. Why? Because DATRON machines are specifically designed for users with little or no machining experience.

The story of DATRON speaks to its simplicity and innovation. Initially, as a manufacturer of electronic PC boards, the company needed a simple CNC machine to create electromechanical components like front and display panels. After purchasing a basic system, they rebuilt it with their engineers, redesigning the hardware and the interface to serve their non-machinist team better.

This redesign eventually became the blueprint for today’s DATRON machines: intuitive, user-friendly, and built for efficiency. Forty years later, DATRON is a full-fledged machine tool manufacturer, no longer in the PCB business, but still guided by the same principle: machining doesn’t have to be complicated, messy, or intimidating.

Why DATRON Is Different

Unlike traditional CNC machines—whose interfaces date back to the 1950s with complex buttons, dials, and G-code—DATRON machines feature a modern, touchscreen interface. It feels familiar, like a tablet or smartphone, with intuitive gestures like swiping, pinching, and tapping. There is no keyboard, and there are no confusing controls.

While the rest of the industry stuck to legacy systems to cater to a shrinking pool of trained machinists, DATRON took a different path—making in-house machining accessible to new users. And with the declining number of trade school graduates, this approach is more relevant than ever.

But it’s not just the control system that makes DATRON unique:

-

Compact, Ergonomic Design: Built with a steel frame and vibration-dampening polymer concrete, DATRON machines offer rigidity without bulk. They’re smaller, less intimidating, and easier to work with.

-

Fast, Simple Workholding: The vacuum table system holds flat parts in seconds—no vises, fasteners, or tape required.

-

Streamlined Workflow: An automated 4-step process makes job setup fast and repeatable.

-

Smart Technology: Features like a live AR camera and 3D touch probe make part alignment visual and precise—no manual measurements or keypads required.

-

Clean Operation: DATRON uses ethanol as a coolant, which evaporates cleanly and leaves no oily mess. Chips are collected dry, with no need for filters or conveyors.

Future-Proofing Your Business

Many manufacturers are waiting to see what happens next—whether tariffs will remain, increase, or be lifted. But with DATRON, your investment pays off either way. Even if tariffs disappear tomorrow, your new in-house machining capability could still be more cost-effective than your pre-tariff outsourcing model.

As John D. Rockefeller once said: “I always tried to turn every disaster into an opportunity.”

Now is the time to seize that opportunity. DATRON can help you avoid tariffs with in-house machining, control your production, reduce costs, and future-proof your business—without needing to become a machinist.