North America | Global

North America | Global

The DATRON neo was specifically designed and built as an industrial, heavy duty, cost-effective solution for high-speed engraving, supporting industries like yours for over 30 years.

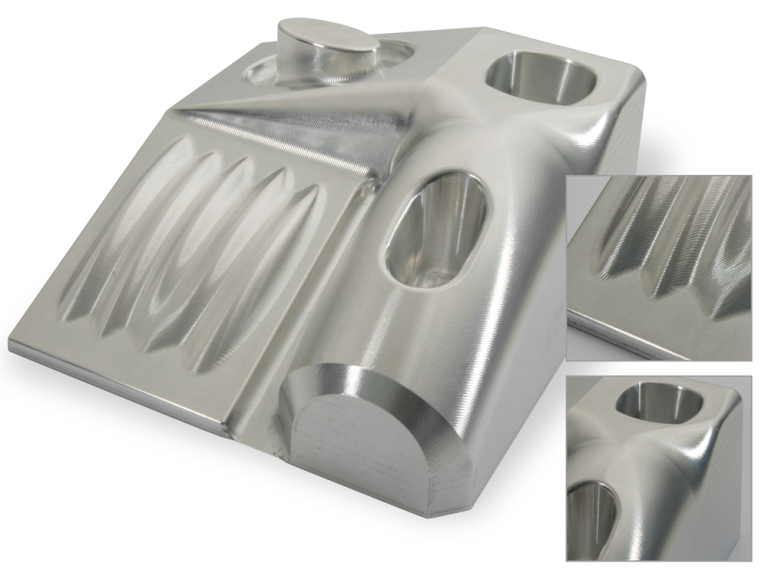

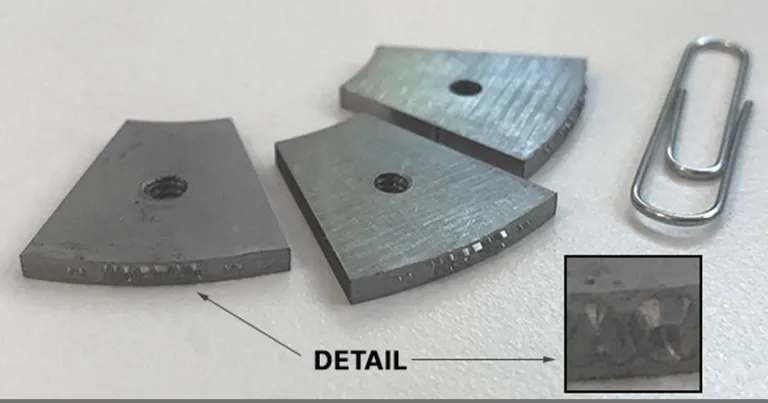

Engrave a wide range of materials such as brass, tool steel, stainless steel, and aluminum with superb surface finishes in a fraction of the time compared to conventional CNC systems. The impressive speed makes this system an excellent economic alternative to acid etching, and it can run overnight 24/7. DATRON is a world leader in engraving solutions for embossing dies, including combination dies, foil stamping dies, steel stamps, rotary die work, shallow cavity molds, serialization, stainless steel panels, and signage.

The plug-and-play system, featuring the DATRON next Control software combined with optional Carveco® engraving software, empowers users in the engraving industry to create three-dimensional artwork in metal with precision accuracy with mirror-like surface finishes. Integrated features like optical cameras and touch probes allow for easy part setup and registration. Integrated work holding, such as our vacuum table systems, makes it easy to secure your plate material in seconds without any gasketing, tape, or mechanical fasteners. There is a plug-and-play 4th rotary axis option for doing cylindrical die work. The touchscreen control lets you tap and swipe to high-precision engraving results in minutes. And remarkably, the DATRON neo even fits through a standard doorway and runs on single-phase power.

Whether outsourcing, manually engraving, using conventional CNC machines, desktop engraving, laser systems, or acid etching, the neo system is a good alternative solution and an easy integration to your operation. DATRON offers turn-key solutions that allow you to be in production on the first day of your installation. Our team of experienced engineers will hold your hand through the entire process, from applying tool paths to your artwork and setting up your tools and workpiece to running and maintaining your engraving machine. Our local inventory of tools, spare parts, and field service technicians nationwide ensures your machine always operates smoothly with minimal downtime. We make it easy.

DATRON has great support here in the States and whenever I have a problem, they help me and respond right away. Having a contact person and service over here is key because if I need a part, I can get it the next day.

Eugene Prohaske, President of DC Graphics

Want to bring engraving projects in-house and get more control of your process? With the DATRON neo, you can handle engraving jobs from design to milling and complete them in just a day—eliminating the wait time, mistakes, and high costs associated with outsourcing.

See the machine engraving here.

The DATRON neo is the ideal CNC solution for the engraving industry, combining high-precision, micron-level accuracy with the ability to deliver flawless finishes in metals like tool steel and brass—all in record time. Unlike traditional, complex CNC machines that take up significant floor space, the neo’s compact, user-friendly design is tailored for engravers working in studios or production environments.

Even if you have never run a CNC machine tool before, this machine enables the creation of intricate, industrial engraving dies with remarkable efficiency and ease. For anyone seeking precision, speed, and convenience in engraving, the DATRON neo is the perfect choice.

Mill Just About Anywhere: Install the neo where you need it. The neo fits through standard office doors and elevators and runs on 230-volt single-phase power.

Achieve Picture-Perfect Precision: Control the built-in camera with augmented reality and simple fingertip gestures like your smartphone.

Begin Milling Almost Immediately: This small yet powerful 3-axis mill, with a fourth rotary axis option, features an easy 4-step workflow and practically skips the machining learning curve.

| Name | Detail |

|---|---|

| Travel | 520 x 420 x 220 mm (20" x 16.5" x 9") (XYZ) |

| Spindle | 2kwatt liquid chilled spindle up to 40,000 RPM |

| Feed | Up to 28 m/min (1,102 in/min) |

| Tool Changer | 24 stations automatic tool changer |

| Control System | DATRON next |

| Working Area | 500 mm x 400 mm (19.5" x 16") |

| Footprint | 805 x 1,290 x 1,880 mm (32" x 51" x 74") (W x D x H) |

| Weight | approx. 700 kg (1,543 lbs.) |

| Touch Screen | 23” touch screen offers a visual interface with the next software |

| Camera | Optical camera in combination with touch screen visually finds parts |

| Probe | Integrated 3D Renishaw Touch probe for precision part finding |

| Coolant | Integrated high-pressure minimum quantity misting system |

| Power | 230 volt single phase on a dedicated 20 amp circuit breaker |

| Name | Detail |

|---|---|

| 4th Axis | for machining cylindrical parts or multi-sided parts |

| Vacuum Table Work Holding | for machining nested parts from flat thin sheet materials |

| Clamping Systems | low profile mechanical and pneumatic vices with soft jaws |

| Dust Extraction Head | for vacuuming and removal of dangerous or abrasive dust particles |

| Remote Software Monitoring | check in on the status of your machine away from the shop |

| Tool Life Management | tool breakage monitoring with automatic duplicate tool replacements |

| Surface Profiling | measurement and mapping of 3D surfaces and compensation of variances |

| Automation Integrations | 24 volt I/O connections for robots / cobots / pallet systems |

| Engraving Software | Carveco® Engraving Software for creating three-dimensional tool paths on artwork or designs |

Our DATRON Experts Help Many Customers Bring Manufacturing In-House. Reach Out To Our Team To See Which Machine And Accessories Are The Right Fit For Your Parts.