- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

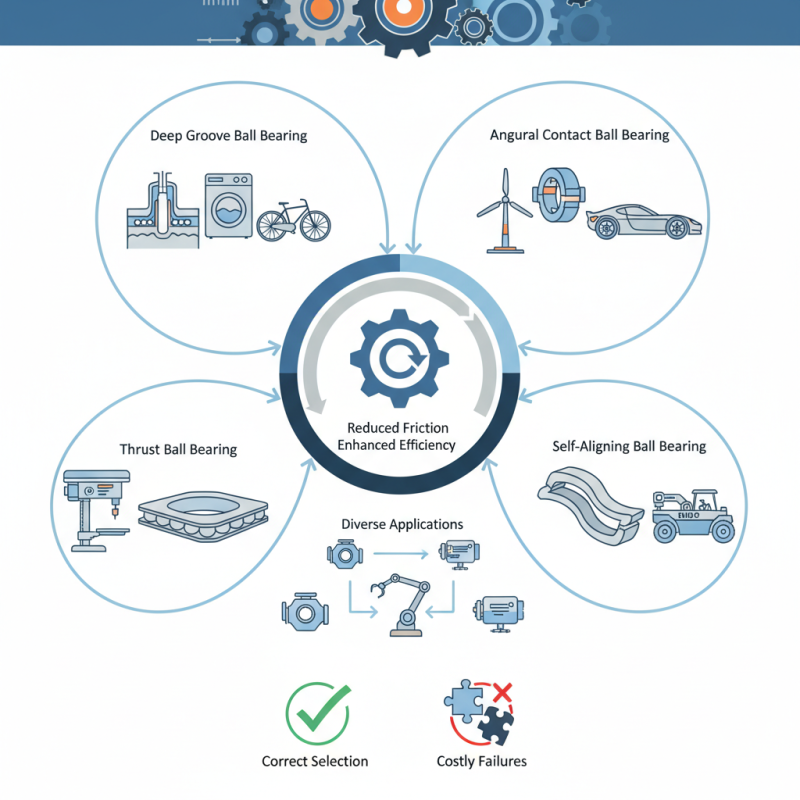

What Are the Types of Ball Bearings and Their Uses?

Ball Bearings are essential components in various machines. They reduce friction between moving parts. By doing so, they enhance movement efficiency and longevity.

Understanding the types of ball bearings is crucial for selecting the right one. Each type serves specific applications. For instance, deep groove ball bearings are common in everyday devices. On the other hand, angular contact bearings are vital in high-speed machinery.

As technology evolves, the usage of ball bearings expands. They appear in everything from electric motors to bicycle wheels. However, choosing the wrong type can lead to issues. It's important to match the bearing to its application. Careful consideration can prevent costly mistakes and failures.

Types of Ball Bearings: An Overview of Common Variants

Ball bearings come in various types, each serving distinct purposes. One common type is the deep groove ball bearing. This bearing can support both radial and axial loads. It is versatile and frequently used in motors and automotive applications. Its design facilitates smooth operations and reduces friction effectively.

Another notable variant is the angular contact ball bearing. This type is engineered to handle higher speeds and greater loads. It features a unique design that allows it to support axial loads in one direction. This makes it ideal for machine tool spindles and gearboxes. However, improper installation can lead to premature wear or failure.

Lastly, stainless steel ball bearings are popular in environments where moisture is prevalent. They resist corrosion, ensuring longevity in harsh conditions. Despite their durability, they can be costlier. Users must weigh initial costs against longevity to make informed choices. Choosing the right type requires careful consideration of specific needs and application environments. The subtle differences in design and functionality are crucial to overall performance.

Applications of Deep Groove Ball Bearings in Various Industries

Deep groove ball bearings are essential components across various industries. Their versatility allows them to operate in different conditions. For instance, they find extensive use in electric motors, which are expected to grow at a CAGR of 4.5% from 2023 to 2028. This growth highlights the demand for efficient and durable bearings.

The automotive sector relies heavily on deep groove ball bearings. They support the performance of engines, transmissions, and wheels. A recent report indicated that the automotive bearing market could reach $18 billion by 2027. This figure emphasizes the critical role these bearings play in ensuring vehicle reliability and longevity.

In the manufacturing domain, deep groove ball bearings improve machinery efficiency. They reduce friction, thus enhancing productivity. However, maintenance challenges persist. Over time, contaminants can affect bearing performance. This can lead to increased downtime and repair costs. Addressing this issue is vital for maximizing their benefits in industrial applications. Regular inspection and proper sealing methods are necessary to mitigate risks.

Ceramic vs. Steel Ball Bearings: Performance and Durability Comparison

Ceramic and steel ball bearings each offer unique advantages. Ceramic bearings are lighter and more resistant to corrosion. Their performance shines in high-speed applications. They have lower friction, which improves efficiency. However, they can be brittle at times. A hard impact can cause damage.

Steel ball bearings are known for their strength and durability. They handle heavy loads effectively. They're often more affordable than ceramic options. Yet, steel is susceptible to rust and wear over time. This can lead to maintenance issues. Their heavier weight can also limit speed.

In choosing between these two types, consider the specific application. High-speed motors may benefit from ceramic bearings. In contrast, heavy machinery may require steel for its robustness. Each choice presents a trade-off. Reflecting on these details will lead to a more informed decision, helping you find the right fit for your needs.

Understanding the Load Ratings of Different Ball Bearing Types

When examining ball bearings, understanding their load ratings is crucial. Load ratings indicate how much weight a bearing can support. These ratings vary among different types. For instance, deep groove ball bearings have a higher radial load capacity. This makes them ideal for motors and industrial applications.

Conversely, angular contact bearings excel in managing axial loads. These bearings work best in assemblies that undergo high-speed operations. However, if misused, they can fail prematurely. It's essential to carefully match the bearing type with specific application needs.

Many users overlook the importance of load ratings. This often results in improper selections, leading to equipment failures. Regular evaluations of the load ratings can prevent costly downtime. Each bearing type has unique characteristics requiring thoughtful consideration. Using the wrong bearing can be a costly error.

Trends in Ball Bearing Technology: Innovations and Market Growth

The ball bearing industry is undergoing rapid changes. Innovations are driving improvements, enhancing performance and longevity. Advanced materials, like ceramics, are now popular. They offer lower friction and higher resistance to wear. This shift reduces energy consumption, appealing to eco-conscious manufacturers.

Trends in technology showcase smart bearings. They can now monitor conditions in real time. This feature helps prevent failures and increases safety. However, the integration of electronics can complicate maintenance. Some users might find it challenging to adapt to these systems. Additionally, cost remains a concern for many businesses.

Market growth is evident as industries embrace these technologies. There is a noticeable rise in automation and robotics. These fields demand high-performance bearings. While the future appears bright, challenges in training and support persist. Companies must prepare their workforce for this evolving landscape. Adapting to these trends is vital but not always straightforward.

Types of Ball Bearings and Their Uses

This chart represents the market share of different types of ball bearings as of 2023. Deep groove bearings lead the market due to their versatility, followed by angular contact and self-aligning types. Thrust and ceramic bearings hold smaller shares but are essential for specific applications.