- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

What is a Roll Lamination Machine and How Does it Work?

A Roll Lamination Machine is a specialized device used in various industries. It plays a crucial role in the lamination process. This machine applies a protective layer to materials, enhancing durability and appearance.

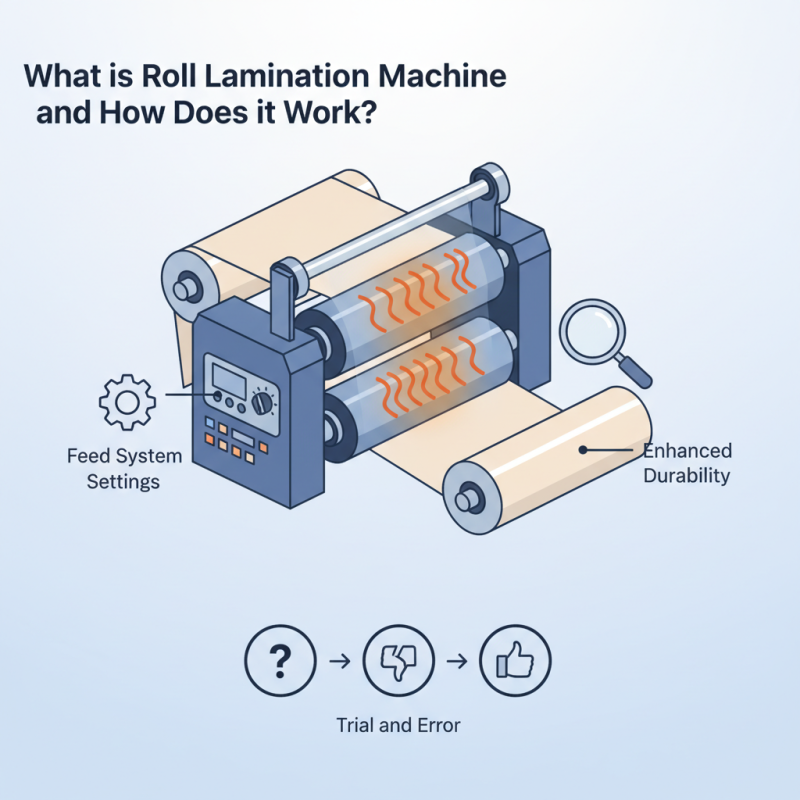

Understanding how a Roll Lamination Machine works involves exploring its components. It consists of rollers, heating elements, and a feed system. These parts work together to bond laminates seamlessly. However, the operation can be complex and may require adjustment.

Users often face challenges when setting up the machine. Each material might need different settings for optimal results. Often, trial and error is necessary to achieve the best quality. Many operators wonder if they are using the machine correctly. Such reflections help improve overall processes and make better products.

What is a Roll Lamination Machine?

A roll lamination machine is a critical tool for various industries. It applies a protective layer to materials like paper, plastic, and metal. This process enhances durability and visual appeal. Roll lamination is particularly useful for packaging, signage, and important documents. Operators load the material onto the machine, which then passes it between heated rollers. Here, the lamination film adheres to the surface under heat and pressure.

When using a roll lamination machine, some tips can improve your results. Ensure proper material alignment before starting. Misalignment can lead to wasted materials and poor adhesion. The right temperature settings are also crucial. Too hot or too cold can cause bubbling or weak bonds.

Cleaning the rollers regularly is vital. Dust and residue can affect the final product. Remember to inspect the quality of the film and the material frequently. If imperfections arise, adjust your machine settings with care. Taking the time to evaluate each step can save resources and time in the long run.

Key Components of a Roll Lamination Machine

A roll lamination machine is essential in various manufacturing sectors. Its design allows for efficient and effective lamination of materials through pressure and heat. Understanding the key components can highlight its importance in production.

The core of a roll lamination machine includes rollers, a heating element, and a feeding mechanism. Rollers compress materials together, ensuring strong bonds. A study from the Lamination Industry Association indicates that machines with optimized roller designs improve output by nearly 30%.

The heating element complements this. It ensures that adhesives are activated at the correct temperature, preventing weak spots in the finished product.

The feeding mechanism is another vital part. It aligns materials to avoid jams and misfeeds. Proper alignment is crucial, as errors here can lead to wasted materials and increased costs. Reports indicate that 15% of lamination failures stem from improper feeding. Observing these components reveals how small changes can significantly affect efficiency and quality. Each part must work in harmony to create reliable, durable materials.

The Process of Roll Lamination: Step by Step

Roll lamination is a fascinating process that enhances the durability of materials. The roll lamination machine plays a critical role in this procedure. It applies heat and pressure to laminate two or more sheets together. This ensures a seamless bond.

The process begins with loading materials onto the machine. The operator carefully adjusts settings for temperature and pressure. Once the materials are in place, the machine rolls them through heated rollers. This action creates the lamination effect. It results in a product that is both strong and aesthetically pleasing.

After the initial lamination, the sheets exit the rollers. Inspecting the output is essential. Sometimes, bubbles or misalignments occur. These imperfections need attention. Adjustments may be necessary to avoid these issues in future runs. Understanding this process can lead to better outcomes in production. Each step is crucial for achieving the desired quality.

Applications of Roll Lamination Machines in Various Industries

Roll lamination machines play a crucial role in several industries. They are designed to bond multiple layers of material together. This process enhances durability and creates a smoother surface. Commonly used materials include paper, plastic, and films. These machines are particularly valuable in the packaging sector, where they help create robust and attractive products.

In the automotive industry, roll lamination machines apply protective coatings. These coatings improve the longevity of vehicle components. Manufacturers use laminated materials in diverse applications, from electronic circuits to interior finishes. The construction sector also benefits significantly. Here, laminated sheets are used for insulation and soundproofing. However, the quality of the output can vary. Operators must be attentive. Minor imperfections in the alignment can lead to waste.

For instance, a misaligned feed can result in uneven layers. This oversight might necessitate rework, which can be costly. It highlights the need for consistent training and quality checks. Sustainability efforts are also gaining traction. More companies are considering eco-friendly materials for lamination. Despite advancements, challenges remain in balancing cost and quality.

Applications of Roll Lamination Machines in Various Industries

Advantages of Using Roll Lamination Machines in Manufacturing

Roll lamination machines play a crucial role in modern manufacturing. They efficiently combine multiple layers of materials to create sturdy products. This process improves durability and flexibility. Manufacturers choose roll lamination for various reasons, emphasizing its advantages.

One significant benefit is cost-effectiveness. This method reduces material waste, ensuring minimal excess during production. It can lower overall expenses, a key aspect for many businesses. Additionally, roll lamination machines increase production speed. They streamline tasks, allowing manufacturers to meet high demand efficiently. Faster production leads to quicker delivery times.

Another advantage is the versatility of materials. These machines can handle various substrates and coatings. This flexibility opens up diverse applications. It's worth noting, however, that not all materials can be effectively laminated. Manufacturers must carefully consider material compatibility. One drawback may be the initial investment cost for high-quality machines. It requires financial planning to ensure a return on investment.